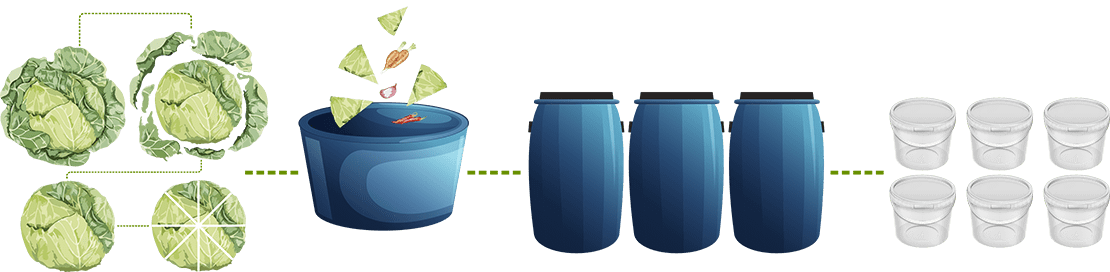

Production Process

1 step

Flat white cabbages first go into the cleaning site of the production process, where the outer and any spoiled or damaged leaves and the cores are removed.

2 step

The cabbages are then cut, shredded, salted and put into a mixing machine.

3 step

Finally, the cabbages are packed into barrels and are tamped down to begin the fermentation process.

4 step

The filling production site starts at the end of 3 conveyor lines. Plastic containers of different sizes are filled with the sauerkraut.

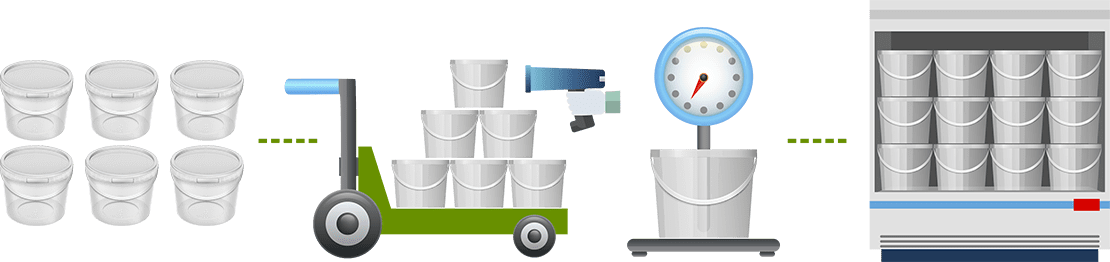

Filling Process

1 step

Plastic containers of different sizes are filled with sauerkraut.

2 step

Each container is then weighed, passed through a metal detector and dated.

3 step

The packed products are then stored in refrigerators, awaiting shipment.

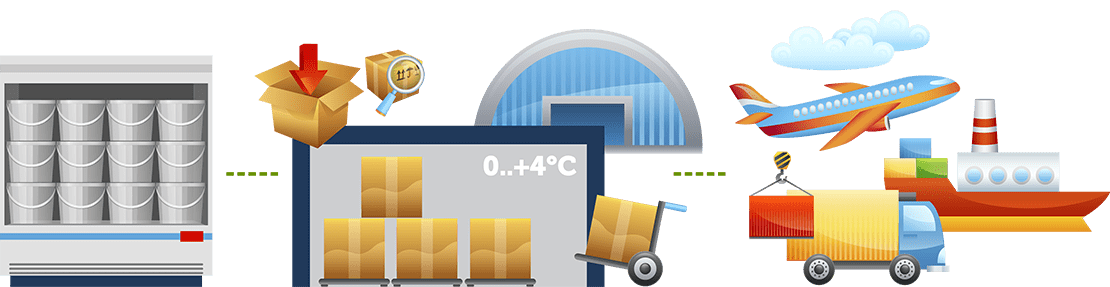

Packaging Process and Delivery

1 step

The packed products are then stored in refrigerators

2 step

At the packaging site, the sauerkraut tubs are packed into boxes and stored in chillers at 0 to 4 deg celcius.

3 step

We deliver our products in reefer containers, set at 0 to 4 deg Celcius. We offer land, sea and air freight. We can also deliver LCL or FCL basis.